charpy v-notch impact test procedure|charpy v notch testing standard : agent According to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: . See more Motociclista morre após ser atingido por ponta de fuzil de poli.

{plog:ftitle_list}

WEBchegou ontem. Eduarda Ribeiro R. Clóvis Beviláqua - Vargem Grande, Pinhais - PR, Brasil. 13 km de Piraquara. Hendy Maia Vargem Grande, Pinhais - PR, Brasil. 14 km de .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See moreIn 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See more

The quantitative result of the impact tests the energy needed to fracture a material and can be used to measure the toughness of the material. There is a connection to the yield strength but it cannot be expressed by a standard formula. Also, the . See moreAccording to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: . See more• Izod impact strength test• Brittle• Impact force See more

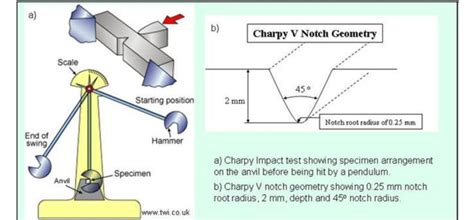

The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the . See moreThe qualitative results of the impact test can be used to determine the ductility of a material. If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with . See more

The impact energy of low-strength metals that do not show a change of fracture mode with temperature, is usually high and insensitive to temperature. For these reasons, impact tests . See more

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .

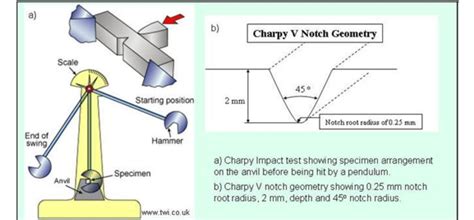

procedure charpy impact test. procedure charpy impact test. The Charpy impact test is one of the impact-testing that is used to determine the resistance towards a sudden load or impact. Impacted specimens with small fracture or .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of ISO documents should be noted. . Kalthoff J.F., Gregor M., Instrumented Impact Testing of Subsize Charpy V-Notch Specimens .

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.

The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . However, in the context of an impact test we are looking at notch toughness, a measure of the metal's resistance to brittle or fast fracture in the presence of a flaw or notch and fast .• Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum • Thermometer • Water • Dry ice • Hot plate . Charpy impact testing machine. Experimental Procedure 1. Place specimens into the available temperature media: • Dry ice .The Charpy V notch test, or Charpy impact test, measures the energy absorbed by a material during fracture. The destructive test method consists of a pendulum, hammer, and a beam of metal placed between two anvils. The energy required to fracture the material provides insight into the material’s notch toughness at various temperatures.

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve? The Charpy test is used to determine the resistance capacity of metal (steel) specimens against the sudden impact of a pendulum that swung from a certain height. The Charpy impact is also known as the Charpy V-notch test because the specimen used in this test is cut at a certain depth in a ‘V’ [.]To conduct Charpy V-notch impact test and determine the ductile-brittle transition temperature of steels. Equipment Coolants . Figure-4: Various criteria of transition temperature obtained from Charpy tests. Procedure Note: Test one material with two specimens for each temperature, 1. Check the zero calibration of the impact tester.

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . Procedure for Charpy Impact Test Specimen Preparation: Prepare a sample with dimensions of 55 mm x 10 mm x 10 mm, featuring a 2 mm notch at the center.. Test Specimen: Elevate the simple pendulum to its initial position and verify the correct adjustment of the testing machine.; Begin by calibrating the Charpy machine -rotate the dial gauge to the maximum . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .

charpy v notch toughness

The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.

The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of ISO documents should be noted. . 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel .The four most common impact-test procedures in use around the world are probably ISO 148 “Steel— Charpy impact test V-notch ,” ASTM E 23 “Standard Test Methods for Notched Bar Impact Testing of Metallic Materials,” EN 10045 “Charpy Impact Test for Metallic Materials,” and JIS Z2242 “Method for Impact Test for Metallic Materials.” How the Izod Impact Test Works. The Izod impact test fixes one end of a notched specimen in a cantilever position by means of a vice. A striker on the arm of a pendulum or similar energy carrier then strikes the specimen. The energy absorbed by the specimen in the breaking process is known as the breaking energy.

The impact test is required to find out the amount of energy a specimen absorbs during fracture. As the notch prepared in the specimen is generally in the shape of the English letter “V”, the process is also popularly known as Charpy V-Notch Test. Charpy V-notch test is widely used in industry to understand fracture problems of materials.

Two standardized tests, the Charpy and Izod, are commonly used to measure Impact Energy (sometimes referred to as Notch Toughness). The Charpy V-notch (CVN) technique is most commonly used in the United States. For both Charpy and Izod, a V-notch is machined into a bar specimen with a square cross-section. A standard V-notch test apparatus is .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and materials development. . PROCEDURE CAUTION: When using the Charpy testing machine, stand well clear of the swinging area of the .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results.

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). Charpy impact testing is often specified as ,in acceptance test for structural materials, and companies performing acceptance tests are typically required to verify the performance of their impact machine periodically. The procedure for verifying the performance of Charpy impact machines has a physical part and an engineering part.

Pendulum Impact Machines: Procedures and Specimens. By T Siewert, T Siewert 1. National Institute of Standards and Technology . & Pauwels, J. "Certification of Charpy V-Notch Reference Test Pieces at IRMM." Pendulum Impact Machines: Procedures and Specimens. Ed. Siewert, T, McCowan, C, & Manahan, M. 100 Barr Harbor Drive, PO Box C700, West .

soft ball caramel test

soft ball stage water test

Conjuntos - Produtos feito na medida para vc se Lambuzar . Conjuntos

charpy v-notch impact test procedure|charpy v notch testing standard